PUMP :CLASSIFICATIONS AND WORKING PRINCIPLES

PUMP :CLASSIFICATIONS AND WORKING PRINCIPLES

A pump is a device which moves fluids by mechanical action, from one place to the other. It is, essentially, the earliest form of machine, dating back to ancient Egypt.

CLASSIFICATIONS

Generally Pumps classification done on the basis of its mechanical configuration and their working principle.

Classification of pumps mainly divided into two major categories:

1.. Dynamic pumps / Kinetic pumps

2. Displacement Pumps / Positive displacement pumps

1. Dynamic Pumps

Dynamic pumps impart velocity and pressure to the fluid as it moves past or through the pump impeller and, subsequently, convert some of that velocity into additional pressure. It is also called Kinetic pumps

Kinetic pumps are subdivided into two major groups and they are centrifugal pumps and positive displacement pumps.

Classification of Dynamic Pumps

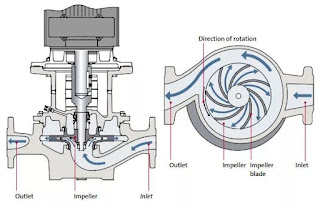

A. Centrifugal Pumps

A centrifugal pump is a rotating machine in which flow and pressure are generated dynamically. The energy changes occur by virtue of two main parts of the pump, the impeller and the volute or casing. The function of the casing is to collect the liquid discharged by the impeller and to convert some of the kinetic (velocity) energy into pressure energy.

An increase in the fluid pressure from the pump inlet to its outlet is created when the pump is in operation. This pressure difference drives the fluid through the system or plant.

a. Radial Flow:

The impeller discharges fluid at right angles to the shaft axis. In this centrifugal pump in which the pressure is developed wholly by centrifugal force. The radial type pumps are used for the application of high head and low discharge.

In radial flow pumps ratio of impeller outside Dia ( D2) to eye Dia ( D1) is 2 or more and impeller having narrow width.

b. Mixed Flow :

The flow direction is partly axial and partly radial. Hence has a result the flow is diagonal. The mixed flow type pumps are used for the application of medium head and high discharge.

In this centrifugal pump in which the pressure is developed partly by centrifugal force and partly by the lift of the vanes of the impeller on the liquid.

In mixed flow pumps ratio of impeller outside Dia ( D2) to eye Dia ( D1) less than 1.5 and impeller having wider width.

c. Axial Flow:

The flow through impeller is parallel to shaft axis low head and very high discharge. The axial flow type pumps are used for the application of medium head and high discharge.

In this centrifugal pump in which the pressure is developed by the propelling or lifting action of the vanes of the impeller on the liquid.

In axial flow pumps ratio of impeller outside Dia ( D2) to eye Dia ( D1) is one and impeller having no width.

d. Axial Split-Case Pumps

Axial split-case pumps have a casing that is split along the center line of the shaft. The impellers can be readily exposed for service and inspection by removing the upper half of the casing. It is also called horizontal split or horizontal split-case pump. Axial-split pumps may be single stage or multistage for higher pressures.

The pumps are usually mounted with shafts in the horizontal position, but vertically mounted pumps for reduced floor space are also available.

B. Vertical Pumps

Vertical pumps were originally developed for well pumping. The bore size of the well limits the outside diameter of the pump and so controls the overall pump design.

Vertical pumps can be subdivided into three major categories

a. Lines-shaft pumps

b. Submersible pumps

c. Horizontally mounted axial-flow

a. Line-shaft Pumps:

The driver is mounted on the discharge head for these type of motors. The line-shafting extend through the column to the bowl assembly and transmits torque to the pump rotor.

b. Submersible Pumps

Submersible pumps (also known as stormwater pumps, sewage pumps, septic pumps) can still operate when being fully submerged in water.

Submersible pumps are close-coupled pumps driven by a submersible motor and designed for submerged installation in a wet well. The motor is mounted below the bowl assembly and is directly coupled to the pump rotor shaft.

C. Fire hydrant systems

Fire hydrant pump system (also known as fire pump, hydrant booster, fire water pump) is technically not a pump but a system by itself. The hydrant booster pump usually consists of 1 centrifugal pump and other components such as control panel and coupled with either a diesel or electric driven motor.

2. Displacement Pumps

Positive displacement pumps, the moving element (piston, plunger, rotor, lobe, or gear) displaces the liquid from the pump casing (or cylinder) and, at the same time, raises the pressure of the liquid. So displacement pump does not develop pressure; it only produces a flow of fluid.

Classification of Displacement Pumps

The mainly Positive displacement pumps are subdivided into three categories as follow

A. Reciprocating pumps

B. Rotary pumps

C. Pneumatic pumps.

A. Reciprocating/Piston/ pumps:

A piston pump is a type of positive displacement pump where the high-pressure seal reciprocates with the piston. Piston pumps can be used in multiple applications and can be used to transfer paint, chocolate, pastry, etc.

In a reciprocating pump, a piston or plunger moves up and down. During the suction stroke, the pump cylinder fills with fresh liquid, and the discharge stroke displaces it through a check valve into the discharge line.

Reciprocating pumps can develop very high pressures. Plunger, piston and diaphragm pumps are under these type of pumps.

a. Plunger / piston type pumps:

The plunger contains the cross head, driven by a cams haft arrangement. The capacity of the pump can be adjusted by changing the stroke, the rotating speed of the pump, or both. The stroke of the pump is changed by the eccentric pin setting.

These types pumps used for the application of sewage, sludge, scum, clarifier thickener underflow. It can be applied for transfer and for metering service. Such pumps are available in single- and multi cylinder models.

b. Diaphragm pumps :

These type of pumps are quite versatile, handling a wide variety of fluids like food additives, chemicals, dry powders, slurries, pharmaceutical products, and wastewater etc. The advantages in diaphragm pumps is the absence of seals or packing, meaning they can be used in applications requiring zero leakage.

B. Rotary Type Pumps

The pump rotor of rotary pumps displaces the liquid either by rotating or by a rotating and orbiting motion. The rotary pump mechanisms consisting of a casing with closely fitted cams, lobes, or vanes, that provide a means for conveying a fluid.

Vane, gear, and lobe pumps are positive displacement rotary pumps.

a. Rotary Lobe Pumps

Lobe pumps contains two elastomer-coated rotors that are driven by an integral gear box and synchronized by timing gears. The rotors run without touching each other or the casing. The liquid is drawn through the inlet port into the pockets between the lobes and chamber walls. Because liquid cannot escape between the two rotors, it discharges in the direction of rotation of the outer lobes through the discharge nozzle.

Lobe pumps offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilise-in-place (CIP/SIP) characteristics. Thus they are very popular in F&B and pharmaceutical industries.

b. Screw Pumps

Screw pumps are a special type of rotary positive displacement pump in which the flow through the pumping elements is truly axial. Screw pumps are high-volume, non-clog, atmospheric -head devices that can pump a variety of solids and debris in raw waste water without screening. Screw pumps, however, have a practical limitation as to pumping head.

c. Progressive Cavity Pumps

A progressive cavity pump is designed specifically to transfer abrasive and viscous fluids with a high solid, fiber, and air content. A hard steel screw rotor rotates and orbits within an elastomer stator.

d. Peristaltic Pumps

Peristaltic pumps creates a steady flow for dosing and blending and is able to pump a variety of fluids, ranging from toothpaste to all sorts of chemicals. They are widely used in water treatment, chemical processing and food processing industries.

e. Gear pumps

Gear pumps transfer fluid by gears coming in and out of mesh to create a non-pulsating pumping action. They are able to pump at high pressures and excel at pumping high viscosity liquids efficiently.

Internal and external gear pumps are the two basic types of gear pumps. The main differences between the two types of gear pumps are the placement of the gears and where the fluid is trapped.

C. Pneumatic Pumps

Compressed air is used to move the liquid in pneumatic pumps. In pneumatic ejectors, compressed air displaces the liquid from a gravity-fed pressure vessel through a check valve into the discharge line in a series of surges spaced by the time required for the tank or receiver to fill again.

Source :

https://bit.ly/2U3A2Qn

Just Share, Catatan Ini hasil googling dan pengalaman. setiap tulisan maupun isi selalu ada tanda "Original" (Hasil karya tulisan saya sendiri), "Copy" (Hasil Googling berikut Sumur). inti dari blog ini tercipta adalah sebagai konsumsi pribadi, namun terbuka untuk pengunjung blog yang membutuhkan. Salam Sukses

Komentar

Posting Komentar